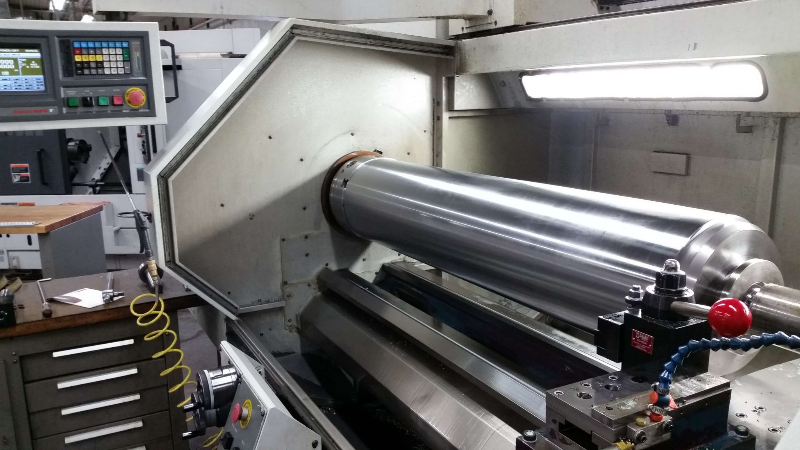

During the manufacturing process, flaws can and often do occur. The finishing process is designed to remove these mistakes. If the metal employed is stainless steel passivation is often the favored choice. As long as the metal does not have a carburized surface, a passivating treatment is applicable and effective.

What Is Stainless Steel Passivation?

Passivation is a process through which a metal is coated or treated to reduce the chemical reactivity of the surface. When the surface of stainless steel components is coated, it helps to take care of any particles of iron that may have been embedded in the surface during any of the following practices:

* Forming

* Machining

* Grinding

* Tumbling

* Lapping

The process makes the surface more “passive.” Through stainless steel passivation, the metal is less affected by the potential negative effects of the environment such as corrosion. The metal becomes stronger and more durable. The finishing process also allows the stainless steel to retain its desired finish.

At the same time as it removes iron particles, stainless steel passivation can take care of other surface problems. It can remove any excess grease and oils. These are all particulates and material that is not found in the original metal but is added through the processes the metal undergoes. Passivation, therefore, is a means of restoring the stainless steel back to its original specifications.

The Treatment

A stainless steel passivation treatment is not complex. After cleaning the metal, it consists of immersing the metal into a special bath. The bath is comprised of an acid. It can be any of the following types:

* Nitric acid

* Nitric acid with sodium dichromate

* Citric acid

The type of bath a company may use depend upon the grade of the stainless steel components as well as other factors. Following the bath, stainless steel components are then neutralized as well as rinsed before they are dried.

Advantages of Stainless Steel Passivation

Subjecting steel to a passivation treatment has several advantages. The major reasons stainless steel passivation is employed are:

* Improves the resistance of the metal to corrosion

* Produces a smooth appearance and an excellent finish that is uniform

* It deburrs the stainless steel giving it the prerequisite polished surface c

* Cleans the metal of all debris, grease, and other deposits

* Improves and increases the longevity of the metal

Stainless Steel Passivation

In the endeavors to decrease the risk of corrosion, finishing companies have adopted a proactive step that includes passivation. It makes the machined components stronger and more resistant. The choice of passivation is a good one, particularly for certain metals. A stainless steel passivation treatment is one-way industrialists can produce steel parts that will successfully fulfill their role in the manufactured environment.